Our Know-how for you.

From order entry to tool delivery, a tool passes through various areas of our Werkzeug-Technologie-Zentrum.

These areas and in particular our competence in these areas are presented in the following list.

We bring your ideas to life.

Our engineering department develops and designs injection moulds to meet the most stringent requirements. In doing so, the focus of our designers is always on ensuring efficient production of the subsequent components. To do this, they employ the latest mould technology! The scope of tasks ranges from minor changes to the development of entire mould systems based solely on an initial specification of the article to be produced.

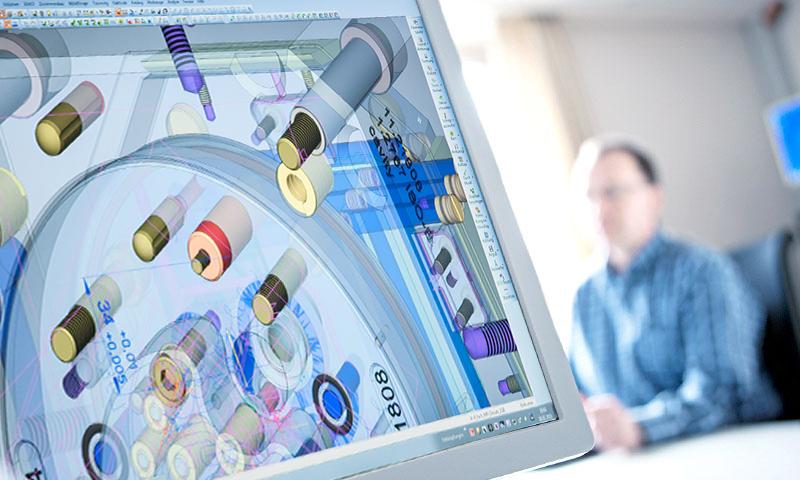

High-tech from the outset: CAD.

At Pöppelmann WTZ, designs are created using the CIMATRON CAD system, which is designed specifically for tool and mould making. With the help of this technology, all standard data formats can be imported without the need for conversion. Furthermore, it is possible to use the data for production purposes immediately. We use the classification of components to increase the parts commonality quota.

Doubly smart: our engineering.

Our engineering department is divided into two areas: The first specialises entirely on technical articles. Here, the focus is on demoulding and tempering as well as the associated article quality. A key core competence in this respect is the quality of the mould surface – incl. the associated production tolerances and processes.

The second part of our engineering department creates moulds for producing thin-walled articles for injection-moulding and thermoforming processes. These offer exceptionally high durability. The very short cycle times also require maximum stability of the moulds. – In order to achieve short cycle times in production, our core competence here lies in the design of the temperature control and the selection of the associated manufacturing processes.

Precision guarantees perfection.

For us – and naturally for our customers – one of the key success factors is precision. That is because it ultimately determines the contour accuracy of our moulds. To achieve tolerances of just 5 µm on formative parts, we machine the components in a dedicated climate-controlled area. After the hardening process, the workpieces receive their final contour. This procedure allows us to ensure reproducibility of individual components and guarantees quality assurance.

Our manufacturing processes in the precision sector range from surface, CNC cylindrical and profile grinding, wire cutting and coordinate grinding to die-sinking EDM. Precision manufacturing is extended by other state-of-the-art production processes such as hard-finished turning and hard-finished milling. With this entirety of processes, the high surface qualities and surface tolerances are achieved.

Go ahead and take a closer look: our quality assurance.

In the area of measurement technology, we verify our high-precision products every day. All specified reference dimensions on the moulded parts are carefully measured, checked, and documented. We can avail of all the main measurement procedures for this purpose. Highly accurate measurements are taken in a separate, climate-controlled measuring room.

With regard to materials, we can also carry out the necessary quality inspections of our components in our WTZ. In this case, we test a range of parameters including the reliable hardness values of the Rockwell scale. We also use a mobile spectrometer to carry out material analyses for steels, copper and aluminium alloys as part of the incoming goods inspection.

In focus: surface quality.

We can check the surface quality of our workpieces with a contour and surface measurement device that scrutinizes the roughness and profile parameters while at the same time monitoring tolerances.

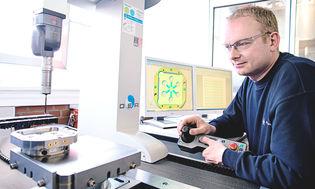

Focusing on best performance: 3D measurement.

Focussed on top-class performance: our coordinate measuring machine takes three-dimensional measurements.

Keeping a modern eye on geometries.

The ultra-modern wave measuring machine is used to check the component geometry.

Bright prospects: the surface finish.

The quality specifications for articles used in the pharmaceutical and food industries are exceptionally strict. For this reason, some of the formative components of our moulds are polished during the final machining step. In the area of mould making, this is a complex process that relies on the skill and years of experience of our employees. For the most part, polishing is still carried out by hand, although polishing equipment using ultrasound technology is also used in some cases. Depending on the application in question, the polishing agents, machining steps, and path motions must be adjusted to the material being processed and its hardness. The final step involves the visual quality inspection using optical aids.

State-of-the-art technology: our machinery.

By using the latest technology, we are able to produce moulds with even greater precision, even faster and – in many cases – more cost-effectively. For this reason, we are constantly updating our comprehensive furnishing park. Some details of the performance of the individual machines can be found below. We are happy to answer any further questions you may have.

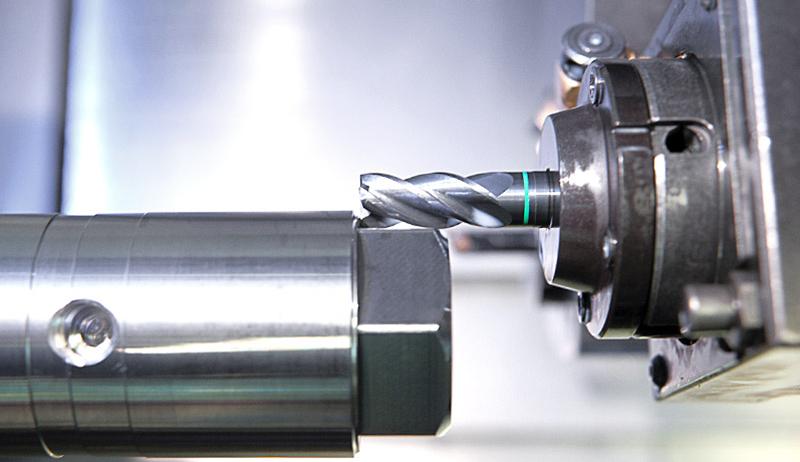

5-axis CNC milling

CNC-controlled 5-axis milling processes allow complex geometries with dimensions of up to 600 mm x 600 mm x 500 mm to be produced.

HSC milling

We machine graphite electrodes and hardened components on our HSC milling unit. The traverse distances are approximately 650 mm x 550 mm x 400 mm.

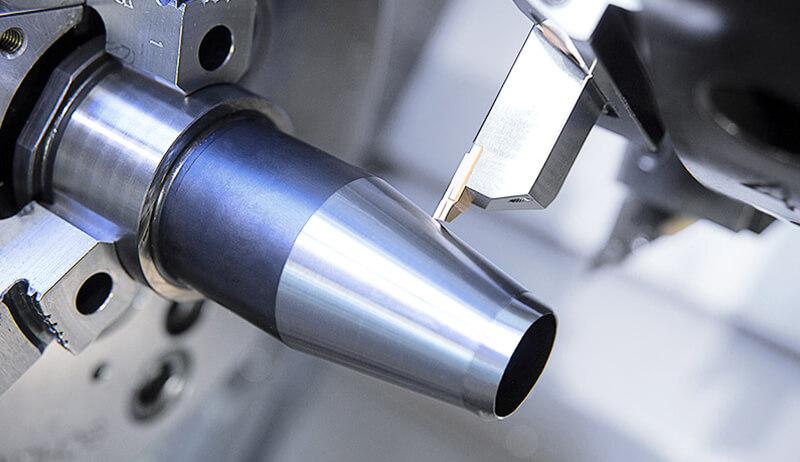

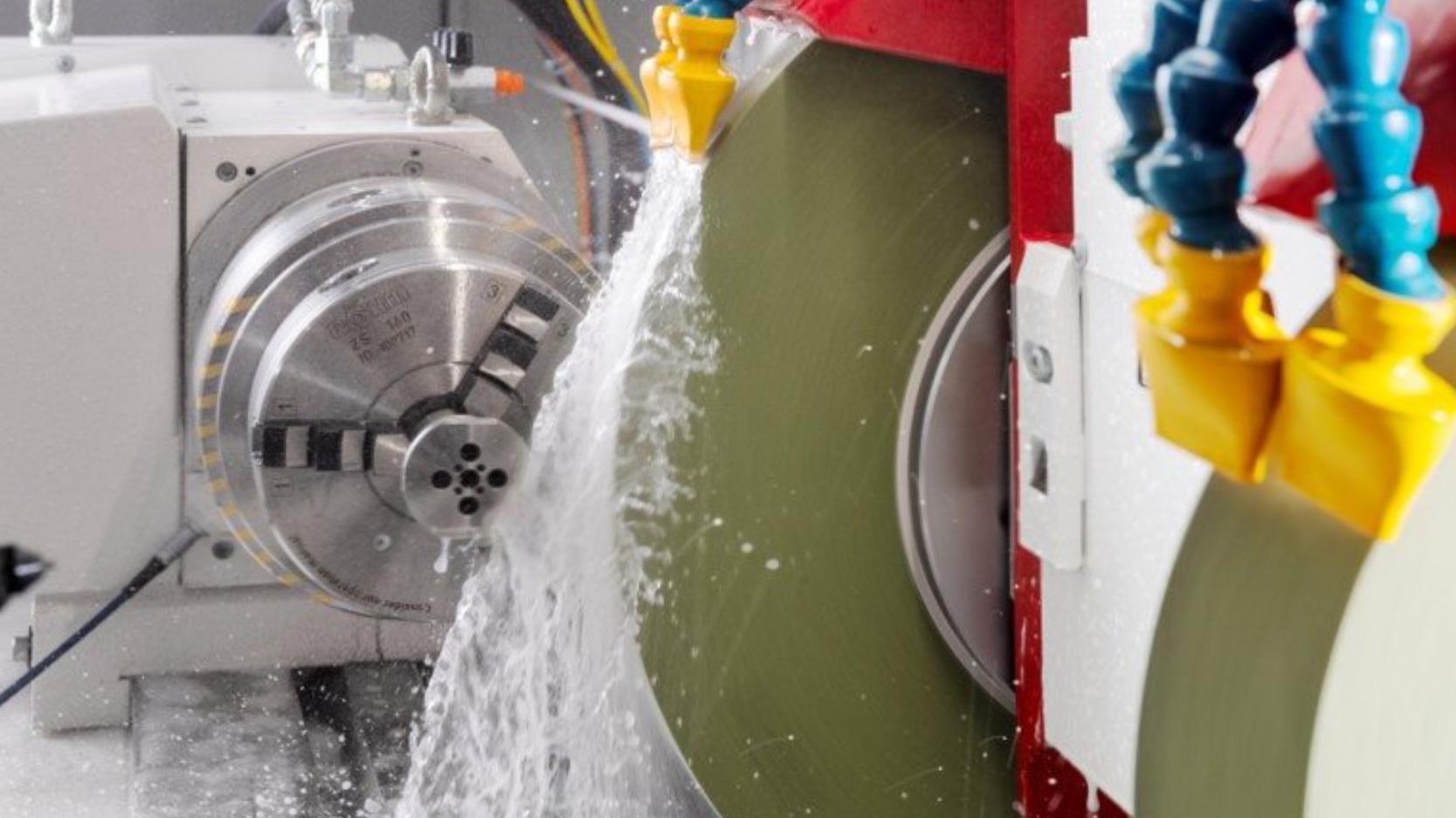

CNC turning

Our daily tasks also include CNC-controlled turning. This process allows us to machine components with a diameter of up to 420 mm and an installation height of up to 1,200 mm.

Hard finish turning

One of the most modern technologies used by Pöppelmann WTZ is finish turning of hardened components – with diameters of up to 380 mm. This often eliminates the need for additional production steps such as grinding.

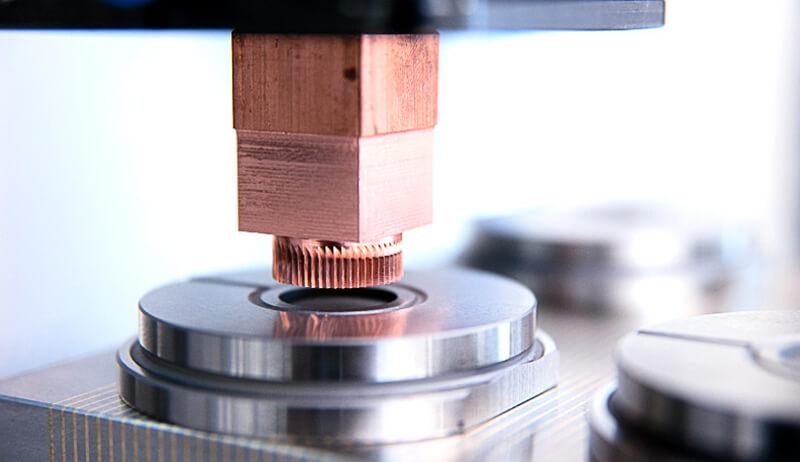

Electric discharge machining (EDM)

In addition to the metal-removing processes, we can manufacture the contoured moulded parts on our EDM machine, which offers maximum traverse distances of 700 mm x 500 mm x 500 mm.

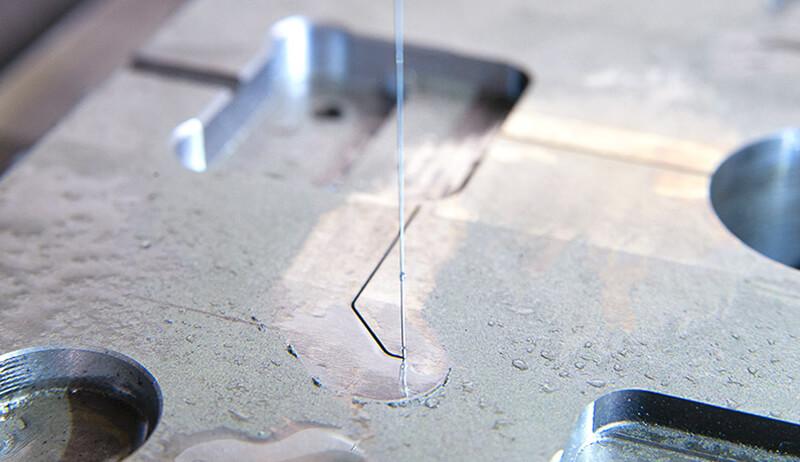

Wire EDM

High-precision contouring is achieved in a variety of ways that includes wire EDM. The traverse paths are approximately 500 mm x 350 mm x 300 mm.

Surface and profile grinding

In our grinding shop, level surfaces and profiles across an area of 1500 mm x 750 mm (with a maximum component height of 500 mm) can be machined.

Jig grinding

High surface qualities are achieved using various technologies that include our jig grinding machines. Here, we can machine components with dimensions of up to 1200 mm x 800 mm.

CNC circular grinding

With CNC circular grinding, round and non-round components can be ground internally and externally up to a diameter of Ø 160 mm with an accuracy of a few µm.

Fully automated to the goal: our production centre.

The WTZ has an automated production centre. This works around the clock, seven days a week - without anyone having to pay attention. A swivel-arm robot travels on a twelve-metre-long track and automatically equips the six machining stations with workpieces that are pre-assembled on workpiece carriers. The system can temporarily store up to 40 workpiece carriers and stands on a floor space of 170 square metres. It links two 5-axis CNC milling machines, a 5-axis HSC milling machine, a die-sinking EDM machine, a 3D coordinate measuring machine and an automated cleaning system.

Convinced?

We are happy to offer you our expertise!

Our services for you.

Precise jig grinding.

On two Hauser machines, we provide jig grinding services that achieve a level of precision down to a few µm. The workpieces to be machined can weigh up to 1,500 kg. Our machines can traverse lengths of 1,200 mm, 800 mm and 170/635 mm (x, y, z/w).

Surface grinding.

Our surface grinding machine supplied by ABA ensures the precision machining of your components – with a surface of up to 1,500 mm x 750 mm. For this purpose, the magnetic table can accommodate workpieces of up to 1,500 kg.

Exact bore holes.

Our modern deep-hole drilling machine can drill bore holes from Ø 4 mm to Ø 25 mm. The precise production of bore holes is possible up to a depth of 800 mm.

Interested?

Get in touch with us!

+49 4442 982-2600

Monday through Thursday: 8:00 a.m.–16:00 p.m.

Friday: 8:00 a.m.–12:00 p.m.

By e-mail

Twenty-four hours a day. We will get back to you as soon as possible.

Interested in an apprenticeship with us?

We train the following professions at the WTZ:

Mould mechanic