Using energy efficiently.

Wir arbeiten täglich an der Verbesserung der Energieeffizienz und entwickeln Maßnahmen zur Reduzierung des Energieverbrauchs. Seit Einführung des Umweltmanagementsystems im Jahr 1996 beschäftigen wir uns intensiv mit den Themen Energieeffizienz und Energieeinsparung. So wollen wir unsere Arbeit sowohl ökonomisch als auch ökologisch in Verantwortung für die Zukunft ausrichten.

Die Herausforderung dabei ist, gleichzeitig die Qualität unserer Produkte zu gewährleisten, die Anforderungen der Produktion und Arbeitsstätten zu erfüllen und Energie einzusparen.

Um diesen Anspruch zu erfüllen, arbeiten wir im Team und kommunizieren offen über alle Ebenen. Die Verantwortung für das Energiemanagementsystem liegt bei dem technischen Geschäftsführer.

In unserer Umwelterklärung berichten wir jährlich öffentlich über unsere energiebezogene Leistung.

Unsere Prozesse für einen effizienten und ressourcenschonenden Energieeinsatz organisieren wir im Rahmen des zertifizierten Energiemanagements nach DIN EN ISO 50001. Wesentliche Aspekte sind dabei die interne und externe Überprüfung, die Kennzahlenüberwachung und die Umsetzung von Maßnahmen.

Die Optimierung des Energieverbrauchs unserer Anlagentechnik ist ein zentraler Ansatzpunkt zur Effizienzsteigerung. Auch bei Bestandsanlagen bewerten wir den Energieverbrauch und nutzen Möglichkeiten zur Optimierung.

Folgende Projekte haben wir bereits erfolgreich umgesetzt:

Energy monitoring

Für die Erfassung unserer Energieverbräuche haben wir eine Vielzahl von Messstellen installiert, die wir kontinuierlich überwachen. Hierdurch ist es möglich, Energieverbräuche zu analysieren und zu bewerten, wesentliche Verbraucher zu identifizieren und Kennzahlen zu bilden. Es ist eine Leitzentrale eingerichtet, die aktuelle Energiedaten und Anlagenzustände erfasst und relevante Daten an die Produktion übermittelt. Diese Informationen sind für die Mitarbeitenden auf Monitoren einsehbar.

Reduction of waste heat losses

Um Abwärmeverluste zu reduzieren haben wir an bestehenden Kälte- und Heizungsanlagen sowie an Produktionsmaschinen Isolierungen angebracht.

Heat recovery systems

Wir verwenden Wärmerückgewinnungsanlagen an unseren Druckluftkompressoren zur Reduzierung des Primärenergiebedarfs zur Beheizung. Außerdem nutzen wir Wärmepumpen zur gleichzeitigen Erzeugung von Prozesskälte und Wärme für Heizzwecke.

Intelligent system control

Unsere Anlagentechnik wird durch intelligente Steuerungstechnik bedarfsgerecht gesteuert. Anlagenzustände und Energieverbräuche werden erfasst und in Prozessvisualisierungen sichtbar gemacht.

LED lighting

Wir modernisieren unsere Beleuchtung fortlaufend. Damit erreichen wir eine bessere Ausleuchtung bei geringerem Energiebedarf.

Electromobility

Für den Werksverkehr und bei einigen Dienstfahrzeugen sind wir auf Elektromobilität umgestiegen.

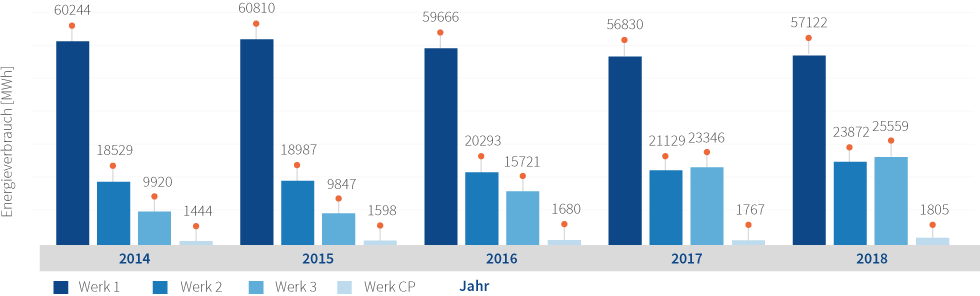

Development of energy consumption [MWh]

Mehr im GRI-Bericht:

Optimal processes secure economy and ecology.

Im Einklang mit unseren Umweltleitlinien haben wir uns verpflichtet, Verantwortung für den gesamten Lebenszyklus unserer Produkte zu übernehmen – von der Herstellung bis zur Verwertung.

Fresh salad and muesli for 40 cents.

Eine Pöppelmann-Geschichte über eine Mahlzeit aus echtem Schrot und Korn, jahrzehntelang erprobte Salat-Klassiker und die Vollwert-Mission der unvergessenen Chefin.

Excellent!

Unser Erfolg ist eng verknüpft mit dem Wohlergehen der Mitarbeiter, Geschäftspartner und der Umwelt. Verantwortungsvoller Umgang mit Rohstoffen und Energie kennzeichnen unsere Philosophie. Seit 1996 kommunizieren wir im Rahmen von EMAS offen über unsere Aktivitäten im Umweltschutz.