From development to series production:

technical components and assemblies as well as packaging –

customised for your application.

Our development competence applies to new technologies, products and markets. Quality, precision craftsmanship and high-tech production are the foundations of our technological leadership.

Customer-oriented and competent: short development times, targeted product optimisation and reliable process planning are our basis. You have quality and costs under control right from the start. Because with us you will find the plastics expertise you need for your project under one roof. From design to fast development tools with virtual product development and optimisation (including CATIA V5, structural calculations (FEM), filling analyses, 3D simulations and DMU visualisations) and in-house toolmaking to efficient high-end series production. A project manager looks after your interests at all times.

The advantages of development at a glance:

- Target-oriented product optimisation and development.

- Modern and fast CAD-controlled development tools.

- Virtual product development and rapid prototyping (including rapid tooling).

- In-house toolmaking with 130 employees.

- Efficient production technologies.

- Fully automated assembly and packaging solutions.

- Everything from a single source. Quality and costs under control right from the start.

Individual design for individual solutions.

Design ideas are implemented by our product designer at short notice. Your demands on design and functionality form the basis of our development work.

Product and packaging design are often the first communication with the consumer. Accordingly, high demands are placed on a new product. Your demands on design and functionality form the basis of our development work. Together we design the targeted product optimisation and the definition of the requirement profile.

Pöppelmann FAMAC® develops solutions that are sensibly designed and thus intuitively usable. In the development and design processes, our product designers primarily pursue the goal of designing the plastic products in such a way that they can be used by as many people as possible without instructions. The design is primarily oriented towards the needs of the users. This results in aesthetic solutions that combine innovative technologies, good design and a high degree of user-friendliness.

The advantages at a glance:

- Our designers can develop new product ideas or optimisations on request.

- Thus, the implementation of Rapid Prototyping enables descriptive design, functional and testing samples to be created quickly and cost-effectively.

- Easy visualisation of packaging ideas using the Pöppelmann FAMAC® 3D studio.

What do you require from your functional part or packaging?

Discover our product development according to eco-design.

At the centre of our efforts for a sustainable use of resources are three Rs, behind which the key words “Reduce”, “Reuse” and “Recycle” are hidden and which we see as the basis for our product development:

Sustainable packaging with significant material savings.

We reduce the use of materials through resource-friendly article concepts and efficient production processes. Our Reduce+ series is not only convincing in terms of its appearance and functionality, but also in particular with regard to a more economical use of resources.

Sustainable packaging thanks to reuse.

We develop products for the consumer goods industry that are intended for reuse. So, the modular system of our rectangular tray series always ensures optimal use of E2 crates in every combination. At the same time, filled boxes can be stacked perfectly and storage capacities almost doubled.

Sustainable packaging made from recycled plastics.

We develop trendsetting concepts to close material loops. Discover our initiative PÖPPELMANN blue® and our new plastic packaging made of post-consumer recyclates (PCR) developed in this context, which was recently awarded the German Packaging Awards 2019.

Individual 3D packaging models – for impressive presentations.

From now on, packaging designers and companies can implement their ideas quickly and easily: with the free 3D Studio. Whether it's a rectangular tray, a round bucket or a square one – the development of a functional packaging design is not just a highly creative task but also a very complex process. Besides the aesthetical point of view, the designer must always take technical parameters into account. Thanks to the 3D Studio, he can now visualize his design ideas in an impressive quality and perform checks completely for free.

To this end he can use the numerous design templates for various products in the standard FAMAC® range, available at www.poeppelmann.com/famac-3d. After the free download, they can be edited in the popular graphics programs and then re-uploaded as PDF. After a short time, the designer receives a freely rotatable 3D model of the custom packaging. Presentations containing these realistic 3D PDFs will not only inspire customers and colleagues, but can also contribute to more efficient meetings. – Discover more in person!

The advantages at a glance:

- Free design service – also suitable for smartphones and tablets.

- Templates for many products in the standard FAMAC® range.

- Compatible with many popular graphics programs.

- Freely rotatable 3D model of individual packaging (3D PDF).

- Easier and more effective coordination with decision makers.

Rapid prototyping – The faster route to series maturity.

From the idea to the model. With rapid prototyping, individual test samples in different materials are available at Pöppelmann already in early development phases.

From idea to model.

We have been working with rapid prototyping in our organisation for many years now (stereo lithography (SLS), selective laser sintering (SLA), 3D printing). When we receive a request for a product, we do not merely devise a drawing for it. Rather, we produce a part that the customer can grasp, feel and test within a few hours.

Manufactured by our 3D printers, which able to produce different – hard or soft – materials. They create prototypes coming very close to the final part. So close that the customer can test its functions under realistic conditions. Therefore, customers can immediately tell whether the part works, if it meets their expectations, which issues have to be addressed and how that should be approached. Through rapid prototyping we show how an idea can be brought into practice in the shortest possible time.

The advantages at a glance:

- Effective. From idea to model.

- Versatile. Design, functional and installation prototypes made of a variety of materials.

- Flexible. 1K and 2K applications.

- Customised. Sheer or colourful finish.

- Economical. Models made without special tools.

- Fast. Time and cost benefits, shorter design times.

- With a plus in efficiency. Samples from real material using rapid tooling.

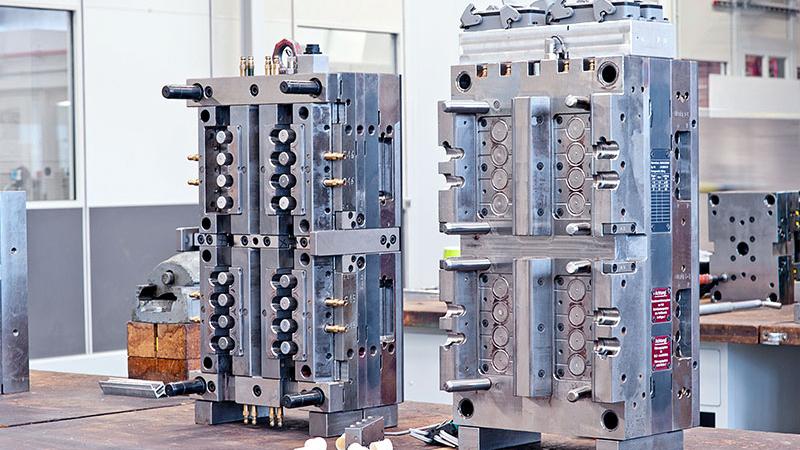

In-house mould shop – more flexibility, know-how and shorter reaction times.

Our services and expertise.

Whether it is the production of new moulds (such as injection moulds or thermoforming moulds), repairs, maintenance work or individual services: Your team at Pöppelmann WTZ is your competent partner in every case. In the following you can get an overview of our many different services.

Would you like to know more? What techniques, processes or computer systems we work with? How Pöppelmann WTZ successfully completes even the most demanding projects? Here you will find the answers! Our competences range from construction to final quality assurance. We also present our large machine park in detail here, including for coordinate grinding or hard finish turning.

You might also be interested in the following topics:

Development

From development to series production.

Technologies

From raw material to finished product.

Quality & hygiene

100 % quality, one effect: long-term cooperation.

Do you have any questions? The FAMAC® team will be happy to answer them.

On-site

Our sales representatives can come straight to your premises. Make an appointment now.

+49 4442 982-3900

Monday through Thursday: 8:00 – 17:00 p.m.

Friday: 8:00 – 15:30 p.m.

By e-mail

Twenty-four hours a day. We will get back to you as soon as possible.