Our spouts and caps offer many important advantages, both for your filling process, for the consumer and the recycling process.

Your benefits

- Patented sealing base which is gentle on the film.

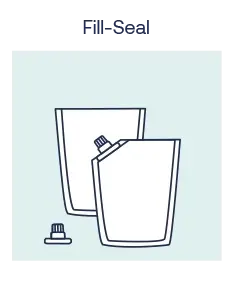

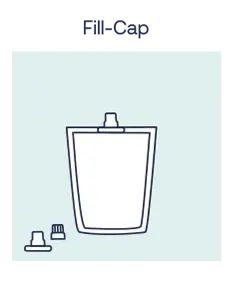

- Solutions for each filling system: Filling through the pouch

and the spout.

- Several materials for recyclable mono-material pouches.

- Spouts for thermal welding and ultrasonic welding.

Our spouts

Stand-up pouches replace existing packaging for pet and baby food, cleaning and laundry products, personal care and dairy products: easy to handle, light weight and reducing waste volume.

The right spouts for your stand-up pouches are available in different sizes - with and without a screw cap.

Find out more about the dimensions here!

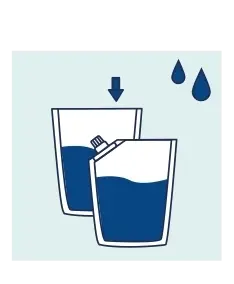

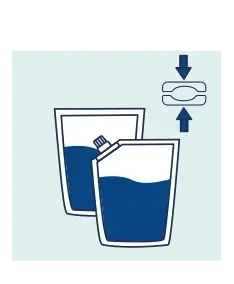

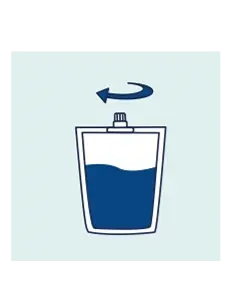

One spout for all types of filling systems.

Sustainability and technology combined:

Realise recyclable pouches with our spouts and caps.

Post-consumer recyclate applications.

Pöppelmann blue®: Use of recycled material:

- Post-consumer recyclate (PCR) applications for the non-food sector.

- Emission reductions through the use of PCR materials.

- Caps and spouts made of PCR-PE and PCR-PP.

Mono-material pouches.

For recyclable mono PE and mono PP pouches:

- Spouts for thermal welding and ultrasonic welding (PP and PE).

- Material options "Low-sealing-PE" for recyclable mono-PE pouches.

- Screw caps with and without tamper-evidence in PP and PE.

Customised solutions.

For customised designs:

- Individual colour design.

- Development of special caps, e.g. flip-top caps

and tethered caps.

- Customised geometries and thread designs.

Our development samples for you.

Together we will find the right solution for your application. Test our development samples of spouts with a diameter of 10.5 mm made from post-consumer recycled material. Fill in the form and test now.