How can we work together to ensure that sustainability has a place at the decision-making table?

More environmental and climate protection thanks to a more responsible use of natural resources is one of the top issues when it comes to the packaging of consumer goods. Manufacturers, packaging specialists and retailers want more sustainable packaging and are therefore intensively involved in the complex challenge of developing not only reliable and attractive packaging, but also more sustainable packaging at the same time.

However, what is sustainable packaging in general?

How we systematically arrive at sustainable packaging that meets all the requirements for product safety, machine compatibility, hygiene and convenience, while at the same time protecting the climate and resources, is the daily challenge of our packaging development, which is carried out in accordance with EcoDesign:

The key words "Reduce", "Reuse" and "Recycle" are the main focuses of our efforts for the sustainable use of resources.

Minimal use of resources!

We reduce the amount of material used through resource-saving article concepts

and efficient production processes (thermoforming before injection moulding).

Optimal packaging concept!

We are developing packaging that is designed for multiple uses. This includes primary and secondary packaging.

100 % post-consumer recyclate!

We are using plastic packaging that also saves 100% of resources and is completely returned to the closed-loop material cycle after use.

Let's give sustainability a seat at the negotiating table.

The sustainability assessment of packaging requires a holistic view. This is because the product to be protected represents the largest share of the ecological footprint. Therefore, the most important task of packaging in terms of sustainability is the safe product protection, so that there is as little (food) loss as possible.

Through EcoDesign, we implement this product safety in the most resource- and climate-friendly way possible - the biggest tool is the circular economy.

The following story shows how we can give sustainability a seat at the decision-making table:

Our challenge: Your product is the focus!

Product protection demands high specifications for the packaging.

Our mission: Let's give sustainability a seat at the decision-making table!

When developing packaging concepts, we consistently implement the requirements of the project participants / stakeholders on the customer side. In doing so, we give sustainability a firm place and place the issues at the centre of our actions. With the aim of achieving holistic ecological and economic optimisation

Transparent assessment base: The evaluation of each development concept is based on the carbon footprint.

In packaging development, the question is clarified together with the customer: What is the best compromise with regard to the diverse requirements of all parties involved? This also includes a transparent and comprehensible evaluation of the various packaging concepts.

Our assessment basis is the carbon footprint. We determine this for our packaging and will be happy to support you in determining it for your complete product.

The right material: Material selection has an influence on resource saving and climate protection.

When selecting materials, various requirements have to be reconciled. In addition to regulatory requirements, the focus must be on the end-of-life issue - in other words, clearly determining what happens to the packaging after use. Design for recycling (D4R) as well as the reuse of the post-consumer recyclate play a very important role.

Sustainability through closed material loop – the PÖPPELMANN blue® initiative.

With PÖPPELMANN blue® we are actively driving the transformation to a circular economy. Since 2018, we have been introducing post-consumer recycled material into series production.

Thanks to the high percentage of recycled plastic in our non-food packaging, we promote the reuse of post-consumer recyclates and thus increase the recycling rate in Germany.

Added values for the food processing industry.

Packaging for the food processing industry cannot be made from post-consumer recyclate for regulatory reasons. For these applications, we focus our packaging development on material reduction as well as recyclability and sortability. And thus realise resource-saving packaging that can be reused after use and returned via the dual systems.

In cooperation with you, we will optimise the packaging design in order to realise the following savings potentials along the value chain:

Material

We reduce the use of materials through resource-saving article concepts and efficient production processes.

CO₂

Plastic packaging contributes to CO₂ reduction because it is particularly light. Combining this advantage with the use of recycled material, high recyclability and environmentally friendly production conditions maximizes the reduction.

Logistics

The stackability and nestability of the cups, bowls and lids can be improved by optimizing the article design. We exploit the quantity per packaging unit in the best possible way.

Wharehouse & power

Existing capacities are optimally used through optimized nestability. The space required during transport and internal and external logistics is reduced, resulting in cost savings.

We rely on innovative ideas and technologies to develop the optimal packaging concept for your product.

Example Reduce+ bucket: 40% material savings!

Thanks to the innovative grid structure, up to 40 percent less plastic is needed to produce the bucket. At the same time, it is very stable, protects its contents from damage and is also eminently machine-compatible.

Available with a cardboard lid made from renewable raw materials, the Reduce+ bucket has a capacity of about 870 ml.

Mono-material packaging with in-mould labelling:

100 % recyclable.

Mono-material or single-material packaging can be ideally sorted, detected and reprocessed in the existing recycling plants.

The focus of our packaging development is therefore on optimizing recyclability - Design for Recycling.

Minimum use of materials.

We use thermoforming to produce mono-packaging from polypropylene - with minimal material input. The cups, trays and lids nevertheless meet our customers' high requirements for stability and machinability.

By using less material, we save raw materials and reduce CO2 emissions along the entire supply chain.

High-quality, lightweight and perfectly recyclable mono-packaging.

We combine many years of experience in in-mould labelling technology with thermoforming know-how. This means that high-quality decor is combined with minimal material use.

This results in resource-saving packaging that is optimally recyclable (mono-material) and reduces CO2 (e.g. in logistics) due to the low material input.

If it needs to be even lighter.

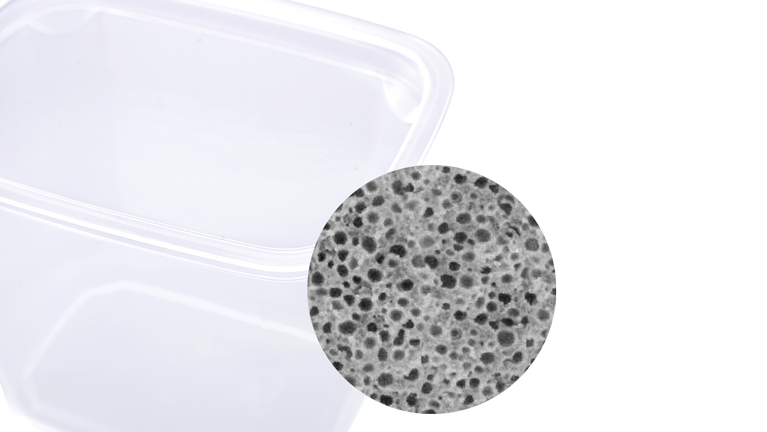

In chemical foaming, blowing agent in the form of masterbatch is added to the plastic granulate, which splits off nitrogen or carbon dioxide in the melting temperature range.

This results in a microcellular foam that provides a weight saving of up to 15 %. The application in polypropylene packaging does not cause any disadvantage in the recycling process (keyword floating-sink separation).

Flexible packaging with weld spouts.

Flexible packaging with spouts and caps as a resource-saving alternative to bottles and canisters.

Stand-up pouches offer considerable advantages in logistics as well as in the storage of empty packaging.

For recyclable mono-material stand-up pouches through low-temperature sealing (low-sealing spouts).

Problem-free and process-reliable implementation on existing systems without extra investment. Particularly economical compared to conventional ultrasonic welding.

Suitable for mono-materials such as PE and PP - and even PCR material. Good recyclability due to the use of mono-materials. Depending on the application, post-consumer recyclates can also be used.

This is how we practise responsibility within the Pöppelmann group:

Sustainable management has been a fundamental factor in our success for decades. The long-term added value of our actions lies at the heart of all of our decisions. This attitude is best described by the notion of "responsibility". We assume this responsibility every day anew – for our employees and the quality of our products, for the natural resources of our planet and for the region which we call home.

We do it. Better.

In joint responsibility for tomorrow.

Thinking ecologically.

Acting economically.

Acting ecologically.

Do you have any questions? The FAMAC® team will be happy to answer them.

On-site

Our sales representatives can come straight to your premises. Make an appointment now.

+49 4442 982-3900

Monday through Thursday: 8:00 – 17:00 p.m.

Friday: 8:00 – 15:30 p.m.

By e-mail

Twenty-four hours a day. We will get back to you as soon as possible.